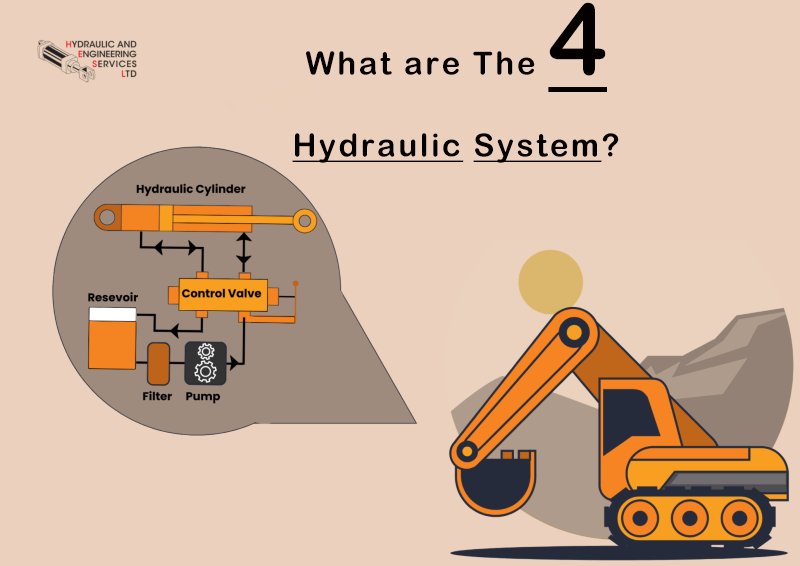

On a construction site, an excavator effortlessly digs earth with its massive bucket; in a factory workshop, a hydraulic press shapes heavy metal plates with a single stroke; in a warehouse, a lifting platform steadily raises several tons of goods to the designated height. These are feats that pneumatic systems simply cannot support. Behind such powerful motions and heavy loads lies the seamless collaboration of hydraulic oil, cylinders, valves, and pipelines — working together to achieve the goals of a hydraulic system.

Cylinder Barrel

The cylinder barrel is the main outer shell of the hydraulic cylinder, made of stronger steel. Its inner surface is finely processed to reduce friction and improve sealing. The cylinder barrel provides a working space for the internal piston and hydraulic oil.

Piston

The piston is located inside the cylinder barrel and is one of the key components of the hydraulic cylinder. It comes into contact with the hydraulic oil and generates thrust or pulling force through the pressure of the hydraulic oil. The piston is made of high-strength alloy materials to withstand the high-pressure oil medium.

Piston Rod

The piston rod connects the piston and extends to the outside of the hydraulic cylinder. It is another key component of the hydraulic cylinder and its primary function is to convert the linear motion of the piston into mechanical force outside the cylinder. Therefore, a hydraulic cylinder is also referred to as a linear motor.

End Caps

End caps are located at both ends of the hydraulic cylinder and are typically made of metal. Their role is to seal the cylinder, maintaining the hydraulic cylinder's integrity and preventing hydraulic oil leakage.

Seals

Seals are critical components in the hydraulic cylinder, typically installed between the piston, piston rod, and cylinder barrel. Their main function is to prevent hydraulic oil leakage and avoid external contaminants from entering the hydraulic cylinder, ensuring system efficiency and stability.

Buffer Device

The buffer device is used to control the piston’s motion speed and impact force, reducing the impact when the piston reaches the end points. It regulates the oil flow to absorb shocks and protect the hydraulic cylinder.

Hydraulic Oil Port

The hydraulic oil port is the interface between the hydraulic cylinder and the hydraulic system, used for the input and output of hydraulic oil. By adjusting the pressure at the oil port, the direction and speed of the hydraulic cylinder’s motion can be controlled.

The calculation formula of hydraulic cylinder force

Basic Formula for Hydraulic Cylinder Output Force

Since air pressure is generally lower, the output force of a pneumatic cylinder is much smaller compared to a hydraulic cylinder of the same size. However, the calculation formulas for thrust and pull for both types of actuators are similar. The output force of a hydraulic cylinder is calculated as:

Thrust Force: F=Phydraulic×Athrust

Return Force: F=Phydraulic×Areturn

Where:

F — Output force of the hydraulic cylinder (Newton, N)

P — Working pressure of the hydraulic system (Pascal, Pa or MPa)

A — Effective piston area (square meters, m²)

A hydraulic cylinder has two types of stroke: single-acting and double-acting, so the calculation of the force area differs slightly. Therefore, the force in different directions for the hydraulic cylinder will also be different.

Thrust

Return Pull Force

Where:

Single-Acting Hydraulic Cylinder:

For single-acting cylinders, one end relies on a spring return, and the return force is typically not provided by hydraulic pressure. The thrust force formula remains: