Sep 24, 2025

In pneumatic systems, hoses and connectors are often treated as secondary components, yet most leakage, pressure loss, and maintenance issues originate right here. Valves and cylinders may define system capability, but hoses and connectors determine whether that capability can be delivered reliably over time. Understanding what they are, how they work together, and how different connection types behave under real operating conditions is essential for anyone designing, assembling, or maintaining pneumatic equipment.

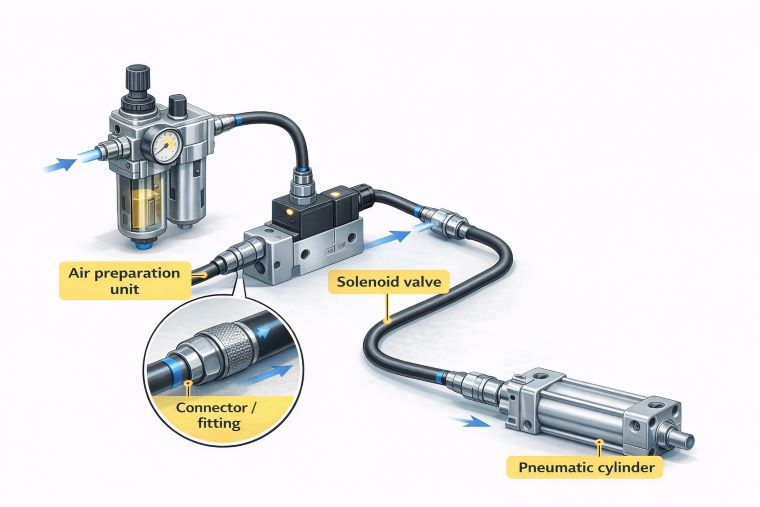

A pneumatic hose is responsible for transporting compressed air between components while accommodating movement, vibration, and installation constraints. Unlike rigid piping, hoses must tolerate repeated flexing, pressure fluctuations, and environmental exposure without cracking, collapsing, or leaking.

Connectors, often called fittings or couplings, provide the mechanical and sealing interface between hoses and system components such as solenoid valves, cylinders, or air preparation units. A connector must hold the hose securely, maintain airtight sealing, and allow assembly or disassembly without damaging either side. In practice, hose performance and connector performance cannot be separated; a high-quality hose paired with an unsuitable connector will still fail prematurely.

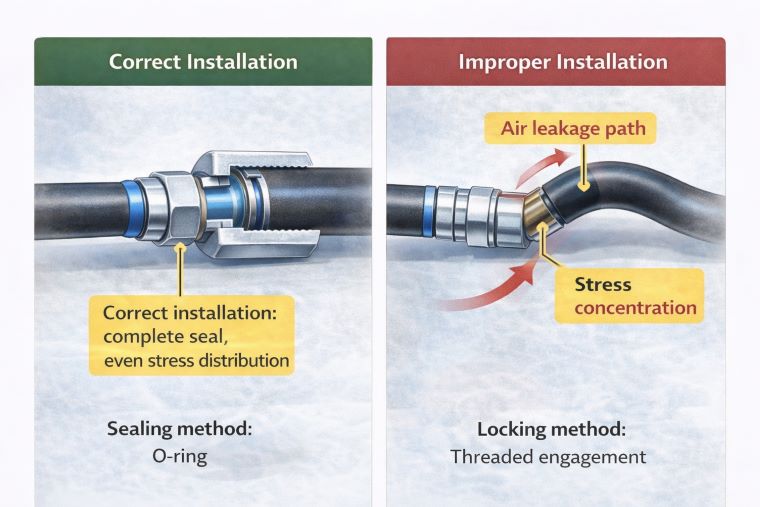

In field troubleshooting, air leaks are rarely caused by hose wall failure. Most leaks occur at the connection point, where sealing depends on geometry, installation accuracy, and operating conditions. Different connection types distribute stress differently, respond differently to vibration, and require different levels of assembly control.

Choosing a connection type is therefore not only a matter of convenience but also a design decision that affects system stability, maintenance frequency, and long-term cost. This becomes especially important in automated equipment where even small pressure losses can cause inconsistent actuator behavior.

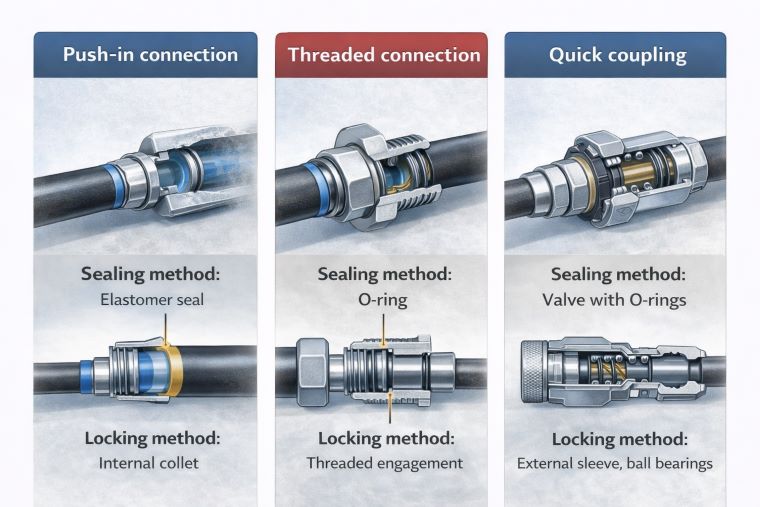

Push-in connections are widely used in modern pneumatic equipment due to their tool-free installation and compact form. The hose is inserted directly into the fitting, where an internal collet grips the outer surface while an elastomer seal maintains airtight contact. This design allows fast assembly and easy hose replacement, making it popular in automation lines and modular machinery.

From a system perspective, push-in connections perform best in applications with moderate pressure, limited vibration, and frequent layout changes. Their sealing reliability depends heavily on hose dimensional accuracy and proper insertion depth. Poorly cut hose ends or repeated removal can damage the sealing surface, leading to gradual leakage rather than sudden failure. For stable installations, this connection type offers an excellent balance between efficiency and reliability.

Threaded connections rely on mechanical thread engagement combined with sealing methods such as O-rings, bonded seals, or thread sealant. They are commonly used where structural rigidity and pressure resistance are more critical than quick assembly. In pneumatic systems, threaded fittings are often found at valve ports, air preparation units, and fixed distribution points.

The key advantage of threaded connections lies in their predictable mechanical behavior. Once tightened correctly, they resist pull-out forces and handle pressure spikes well. However, their sealing performance is highly dependent on correct torque and thread alignment. Over-tightening can deform threads or seals, while under-tightening results in micro-leakage that may only appear under load. For systems exposed to vibration or thermal cycling, proper sealing design becomes especially important.

Quick couplings are designed for applications where frequent connection and disconnection is required without shutting down the entire air supply. Internally, they use spring-loaded valves that automatically seal when disconnected, preventing air loss and improving operator safety.

In industrial environments, quick couplings are often used for tooling, test stations, or auxiliary air lines rather than permanent system connections. Their value lies in operational flexibility, but this comes with trade-offs. Compared to push-in or threaded connections, quick couplings introduce additional internal flow restrictions and sealing interfaces. For precision pneumatic control, they are best placed where convenience outweighs minimal pressure loss.

Selecting a connection type should always start from how the system actually operates, not from catalog preference. Equipment that cycles continuously with minimal vibration favors stable, low-maintenance connections. Mobile machinery or modular equipment benefits from connections that tolerate movement and repeated handling.

Environmental factors also play a role. Oil mist, cleaning chemicals, temperature variation, and UV exposure can all affect sealing materials over time. A connection that performs well in a clean assembly line may fail prematurely in a dusty or high-temperature environment. Matching connection design to these realities reduces hidden failure modes that only appear after months of operation.

Most connection failures are not caused by defective components but by mismatched design assumptions. Using push-in fittings with hoses outside tolerance, applying thread sealant incorrectly, or mixing incompatible materials are frequent sources of trouble. Another common issue is ignoring hose routing; excessive bending near the connector increases localized stress and accelerates seal wear.

Good practice involves consistent hose cutting, controlled installation torque, and periodic inspection at connection points rather than only at active components like valves or cylinders. In many cases, improving connection quality has a greater impact on system reliability than upgrading major components.

Air leakage at connection points does not always produce audible noise, but it directly affects energy consumption and control accuracy. Even small leaks force compressors to run longer and reduce effective pressure at actuators. Over time, this leads to higher operating costs and inconsistent machine behavior that is difficult to trace.

By treating hoses and connectors as functional components rather than accessories, system designers can achieve more predictable performance and longer service intervals. In well-designed pneumatic systems, connection integrity is considered part of the control strategy, not an afterthought.

(FK9027)

The principle and characteristics of vacuum generators

The principle and characteristics of vacuum generators

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Action Delay of 2-Way Solenoid Valve in Long-Pipe Installation

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pilot Orifice Blockage: Hidden Risk in Micro Passages of Solenoid Valve

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

Pneumatic Vacuum Filter: Design Differences between SMC Type and Common Filters

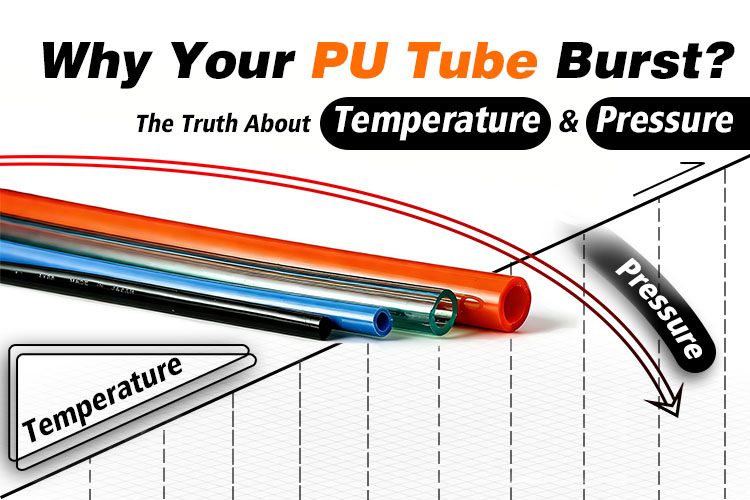

Why Your PU Tube Burst? The Truth About Temperature & Pressure

Why Your PU Tube Burst? The Truth About Temperature & Pressure

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap