- sales@fokca.com info@fokca.com

- WhatsApp: +86 150 5749 1870

Sep 30, 2025

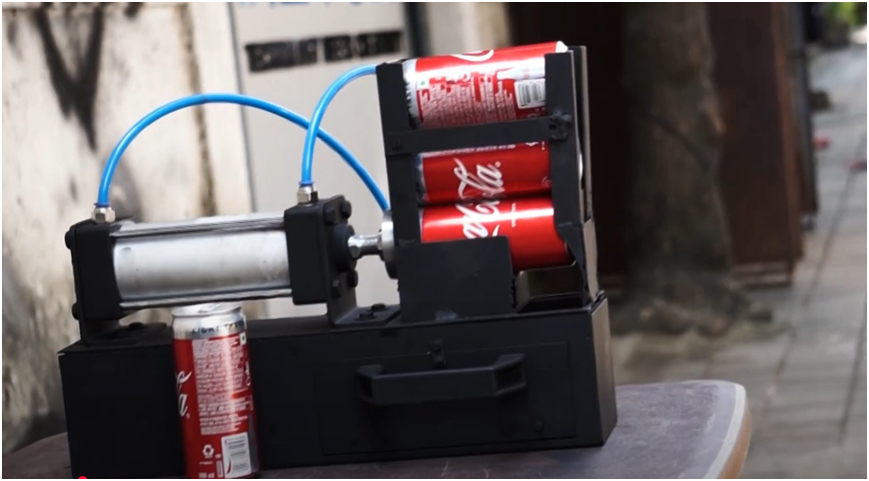

For a long time, people have used manual can crushers to compress used cans. Crushing cans by hand is a difficult and very labor-intensive process. Therefore, we propose a pneumatic-based can crushing system that enables fully automatic can compression.

The can crusher can compress cans and metal tins with a capacity of up to 30 liters, reducing their volume by up to 90%. This compact and durable crusher contains no electrical components, making it easy to maintain and clean. It can compress almost all types of non-aerosol cans, including metal, steel, tin, and aluminum, with a maximum capacity of 30 liters. Whether in food production or manufacturing processes, many cans and metal tins contain waste liquids, such as oil, paint, or water, the handling of which is both troublesome and costly.

Pneumatic Actuator

Pneumatic Pipes

Pneumatic Fittings

Pneumatic Valves

Supporting Bed

Crushing Bed

Supporting Frame

Mounts & Joints

Can Tray Assembly

Electronic Circuit

Automatic Can Crushing

The pneumatic can crusher operates fully automatically, eliminating the need for manual labor. Users can compress cans effortlessly, improving workplace efficiency and reducing fatigue.

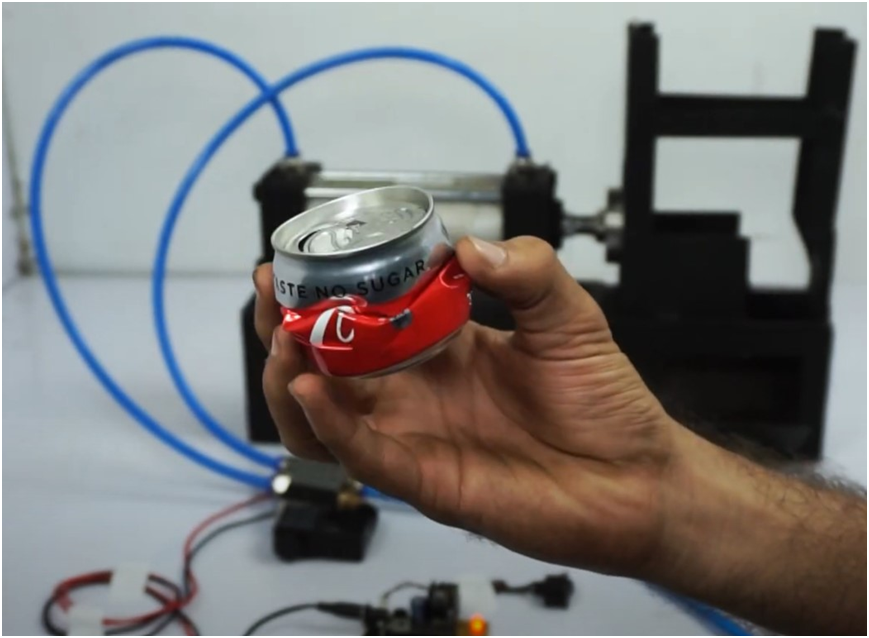

Efficient and Consistent Compression

The system delivers uniform crushing results every time, reducing the volume of cans by up to 90%. This consistency ensures optimal space utilization in waste management and recycling.

Easy Waste Handling

By compressing metal, steel, tin, and aluminum cans—even those containing residual liquids—the crusher simplifies waste disposal. It minimizes mess, reduces handling costs, and streamlines recycling or waste processing.

What is an FRL, and why is it so important for a pneumatic system?

What is an FRL, and why is it so important for a pneumatic system?

From Manual to Intelligent: How Pneumatic Compression Machines Achieve Automation Transformation

From Manual to Intelligent: How Pneumatic Compression Machines Achieve Automation Transformation

A Beginner's Guide to understand the difference about pneumatic components and automatic device

A Beginner's Guide to understand the difference about pneumatic components and automatic device

Harnessing Compressed Air: A Study on Pneumatic Devices and Their Applications

Harnessing Compressed Air: A Study on Pneumatic Devices and Their Applications

What are the components of a hydraulic actuator?

What are the components of a hydraulic actuator?

You May Interest In

Apr 18, 2025 Blog

What is an Angle Seat Valve?Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap