Dec 09, 2025

Pneumatic equipment is highly dependent on clean and stable air supply to operate reliably over long periods. Without proper air preparation, contaminants like moisture, dust, and oil can gradually damage seals, clog valves, and cause irregular equipment behavior, leading to costly repairs and reduced system lifespan.

FRL units mitigate these risks by filtering impurities, regulating air pressure, and providing precise lubrication where needed. As a result, they protect sensitive components from wear and corrosion, keeping pneumatic systems in optimal condition. Recognizing the importance of FRL units is key to maximizing equipment longevity and ensuring long-term operational stability.

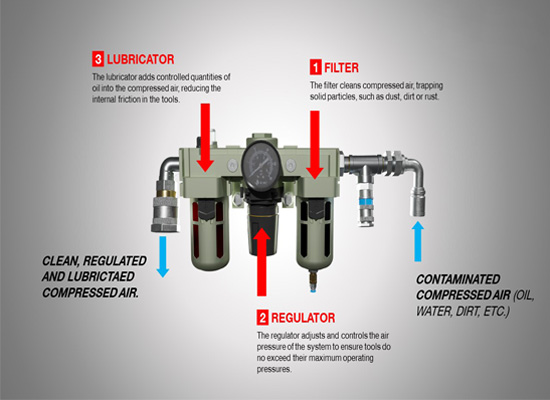

An FRL is a air preparation component for pneumatic tools, consisting of a filter, pressure regulator, and lubricator.

The air discharged from the compressor can be contaminated with oil, dust, water particles, etc., which can damage downstream equipment and shorten its lifespan. Therefore, compressed air needs to be cleaned and lubricated before leaving the system. This is where the air purifier (FRL) comes in!

The FRL delivers clean air at a constant pressure and lubricates it as needed to ensure proper operation and extend the lifespan of pneumatic tools.

◆ Using pneumatic tools and equipment.

◆ Requirement for clean air.

◆ Improving the lifespan, safety, and reliability of the air system.

Each part of the FRL functions differently, but these three components work together to achieve the following goals:

Filter (First Stage):

This filter, through the combination of a separator and valve core, removes moisture, dust, and other harmful impurities from the air system, achieving the first stage of purification of the compressed air.

Regulator (Second Stage):

The regulator is used to regulate and control the air pressure in the system to ensure that downstream components do not exceed their maximum operating pressure.

Lubricator (Final Stage):

The lubricator reduces internal friction in tools or equipment by releasing a controlled mist of oil into the compressed air. Antifreeze may also be added to the lubricant to prevent the tool from freezing in winter.

Other websites offering similar products include:

www.universal-robots.com: Lightweight, highly flexible, and easily programmable collaborative robots

www.sick.com: Supplier of high-reliability, industrial-grade products

www.automationdirect.com: Offers affordable and readily available automation components

www.machinedesign.com: Technical articles, product reviews, and design case studies for industrial automation

www.moog.com: Precision control components for aerospace, industrial machinery, and defense

www.automate.org: A platform for professional exhibitions and exchanges in the automation industry

www.balluff.com: Provider of industrial sensing and automation solutions

(9016)

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Globe Valve Installation Direction Errors and Corrosion Risks You Can’t Ignore

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

Limitations of Globe Valves in Low-Pressure, High-Flow Systems

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

ED Seal vs O-Ring in Flat Sealing Systems: Which Delivers Better Sealing Performance

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Why Hydraulic Quick Couplers Are More Prone to Seepage Under High Pressure

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

Installation Considerations for Angle Seat Valves in Vertical and Horizontal Pipelines

You May Interest In

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap