Nov 24, 2025

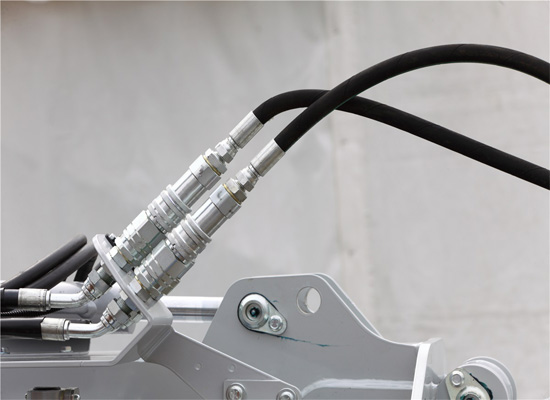

Hydraulic quick couplers make it possible to connect and disconnect fluid lines quickly and conveniently without causing fluid loss or pressure drop. They allow users to rapidly attach hydraulic hoses to machines or piping systems. Designed with precision for specific fluid applications, hydraulic quick couplers typically consist of two components — a male half and a female half. When properly connected, these two parts form a secure, leak-free seal that ensures smooth and uninterrupted fluid flow.

Ball-lock mechanism for secure connection.

Built-in shut-off valve prevents oil backflow.

Metal-to-metal or elastomeric sealing; excellent interchangeability.

When the male and female couplings connect, the locking balls engage automatically, opening the internal valves to allow flow. Disconnecting closes the valves to stop leakage.

Industrial machinery, construction equipment, agricultural machines, hydraulic tools, injection molding equipment.

Ball-lock system with a simplified, higher-flow design.

Strong resistance to impact pressure and heavy-duty cycles.

Push-to-connect operation with automatic steel ball locking; valves open when connected and close upon separation.

Agricultural machinery, forklifts, tractors, light construction machinery, hydraulic attachments.

Open-type design without internal check valves.

High flow rate and very low pressure drop.

Built to meet Japanese industrial standards.

Flow is only allowed when the couplings are connected. No valve means the hydraulic system must control leakage.

Excavator attachments, hydraulic breakers, agricultural equipment, Japanese-standard machines.

Similar to Japanese open types, but built to U.S. dimensions and thread standards.

Robust design for high-impact hydraulic systems.

No internal valves; relies on the hydraulic system’s own pressure and shutoff control.

American-market machinery, hydraulic tools, agricultural systems, construction equipment.

Thread-to-lock connection preventing accidental disconnection under high pressure.

Excellent resistance to vibration and pressure spikes.

Equipped with internal shut-off valves.

After the male is pushed in, a threaded sleeve is tightened to fully lock the coupler. Valves open during connection and close when uncoupled.

High-pressure hydraulic systems, mining equipment, oil & gas machinery, heavy-duty industrial circuits.

Flat-face sealing eliminates oil spillage during disconnection.

Easy to clean; prevents dirt from entering the system.

Plunger-style valves provide stable and balanced flow.

When connected, the flat faces push against each other to open the valve. When disconnected, both valves seal instantly to prevent dripping.

Excavators, construction machinery, hydraulic attachments, environmental equipment, frequent tool-change environments.

One-hand operation; automatic locking when pushed in.

Often designed with a protective sleeve for direct pull-to-release.

Suitable for low- to medium-pressure systems.

Insert to lock; pull the outer sleeve to disconnect. No manual sleeve pulling is needed during insertion.

Agricultural machinery, mobile hydraulics, low/medium-pressure systems, equipment requiring quick hose changes.

Manufactured from 304 or 316 stainless steel for superior corrosion resistance.

Available in ball-lock, flat-face, and threaded types.

Operating method depends on the selected structure (ball-lock / flat-face / thread-lock designs).

Marine equipment, chemical processing, food-grade machinery, high-corrosion environments.

Designed specifically for medium-pressure hydraulic circuits.

Compact body with stable sealing performance.

Commonly uses ball-lock design with internal valves that automatically close when disconnected.

Agricultural systems, industrial equipment, medium-size construction machinery.

Internal ball valve structure ensures a reliable shut-off.

Full-flow design for maximum fluid throughput.

Suitable for viscous or contaminated fluids.

The ball valve opens when connected and closes instantly upon disconnection to prevent oil return or leakage.

Oilfield machinery, chemical equipment, high-flow hydraulic systems, industrial processing lines.

You May Interest In

Nov 26, 2025 Blog

How to use hydraulic quick coupler?

Nov 25, 2025 Blog

How to replace hydraulic quick coupler?

Nov 23, 2025 Blog

How to identify hydraulic quick coupler?

Sep 01, 2025 Blog

A Guide to 6 Common Hydraulic Quick Coupler ProblemsLinks: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap