Fokca Pneumatics produces pneumatic actuators of different types and functions, and also has types that can serve as alternatives to the relevant series of festo, smc, and airtac.

What is a pneumatic cylinder?Pneumatic air cylinders are the most critical mechanical action components in a pneumatics. The working principle of a cylinder is to convert the pressure energy of compressed air into mechanical energy to drive external loads, producing linear or rotary motion to perform actions such as pushing, pulling, clamping, lifting, and rotating.

Air Cylinders include standard cylinders, compact cylinders, rodless cylinders, guided cylinders, miniature cylinders, and rotary cylinders, and are widely used in automated production lines, robots, food and beverage equipment, chemical processing, pharmaceuticals, and laboratory automation.

The compressor air pneumatic cylinder has two working principles: the first is to drive the load to perform linear action, and the second is to drive it to perform rotary acting motion.

The following is an introduction to the two types of operation modes.

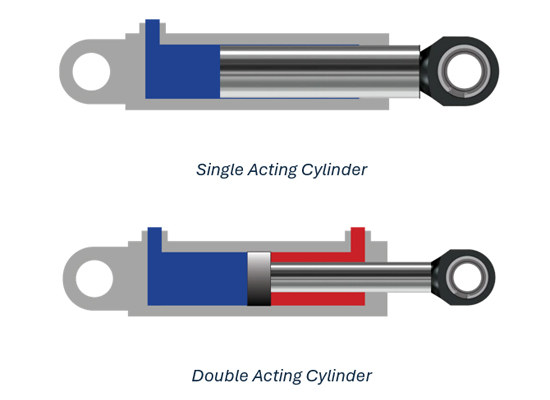

Linear motion actuators are available in two types: single-acting and double-acting.

● Single-Acting Cylinder

This cylinder action is driven by compressed air in one direction, returning via an internal spring.

● Double-Acting Cylinder

Compressed air alternately drives movement in both forward and backward directions, this action cylinder offers stronger and more stable performance.

Rotary cylinders output fixed-angle rotational motion, commonly used in:Fixture rotation,Sorting robotic arms,Valve actuation.

Standard cylinders offer strong versatility, multiple bore sizes, and flexible stroke lengths (commonly 25–1000 mm). Fokca provides three main standard cylinder series:

(1) ISO 6431 Pneumatic Cylinder

DNC Series – Compact and Lightweight

◆ 20% smaller volume vs. standard ISO6431

◆ Suitable for equipment with limited space

◆ Medium load capacity

SI Series – High Precision, High Durability

◆ Ideal for medium to long travel

◆ Integrated magnetic switch slots

◆ Stable performance

DNG Series – Enhanced Impact Resistance

And enhance the impact resistance of DNG Series pneumatic cylinder, designed for high-frequency and heavy-load applications.

(2)Airtac Standard Pneumatic Cylinder

The SC series cylinder, with a structure of 20-100mm, is more compact and competitively priced. Its installation size is partially compatible with ISO standards, making it suitable for cost sensitive general industrial applications and retrofitting of ordinary equipment.

Ultra compact design, with a width reduced by 25% compared to ISO standards and a cylinder diameter range of 10-25mm, SU series cylinder is suitable for limited space and special dust-proof design.

(3)SMC Standard Air Cylinder

MBB Series cylinders are built in dual guide rod structure, strong lateral force resistance, suitable for eccentric loads.

Low friction sealing technology, with a speed of up to 1.5m/s (0.5m/s for ordinary cylinders). The starting pressure is as low as 0.02MPa, and the response is sensitive. The seal has a long lifespan,

CA1 CDA1 series cylinder without lubricating oil for piston rod.

This type of cylinder uses an internal piston to drive an external slider for linear reciprocating motion, offering long stroke capability while saving installation space.

This type of guided cylinder features two parallel guide rods that provide high lateral stability and torque resistance, ensuring smooth and precise linear motion for heavy-load or high-precision applications.

Fescolo is our official cylinder brand,visit website and you will learn more pneumatic cylinder types. If you need customization, we can also discuss specific production plans.

◆ The most common function of cylinder actuator is to convert air energy into linear action energy.

◆ The cylinder can also be used to clamp workpieces or mechanical components.

◆ Pneumatic cylinder can also receive control signals from the system to achieve output motion.

◆ It can also serve as a basic component for driving pneumatic devices and machines to achieve automated operation.

Pneumatic cylinders have become the most commonly used actuators in industrial automation and pneumatic systems, thanks to their multiple advantages listed below.

◆ Simple structure and easy replacement of components

◆ Fast response, suitable for frequent and continuous operation

◆ Powered by compressed air, clean and environmentally friendly

◆ Low material cost, easy to manufacture, and readily available supply

◆ Supports automatic control and logic interlocking

◆ Wide range of product types and application industries

For cylinder maintenance, you can follow these steps:

◆ Regular inspection of seals

◆ Keep cylinder components clean, especially moving parts.

◆ Lubrication

◆ Check installation and fasteners

◆ Check air lines and valves

For cylinder repair, you can follow these steps:

◆ Fault diagnosis

◆ Disassembly and inspection

◆ Replace damaged parts

◆ Cleaning and lubrication

◆ Reassembly and testing

Fokca is an industrial air cylinder manufacturer,and Fescolo is our official cylinder brand name, you can visit fescolo website where you can explore more pneumatic cylinder types, product details, and customization services. If you require OEM/ODM or non-standard design, we can discuss tailored production solutions.Contact us.

A pneumatic cylinder is a linear action component in a pneumatic system that converts compressed air energy into straight-line (linear) mechanical motion. It is commonly used to perform actions such as pushing, pulling, lifting, or clamping in industrial automation and machinery.

A pneumatic cylinder typically consists of three types of components, including internal moving components, sealing components, and other structural and functional components.

Internal moving parts include the piston, piston rod, and cylinder.

Seals include piston seals, piston rod seals, and dust rings.

Other structural and functional components include end caps, buffer devices, guide sleeves, intake and exhaust ports, and mounting accessories.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap