Specification:

| Material | Thermoplastic Ester-Based Polyurethane |

| Applicable medium | Air, Water, Vacuum |

| Working pressure range | 0~1.0MPa |

| Burst pressure | 2.4~3.0MPa |

| Embient and fluid temperature | -20℃~+80℃ |

| Hardness Shore A | 95A ASTM D-2240 |

| Tensile strength(kg/cm2) | 600 ASTM D-638 |

| Ultimate elongation(%) | 490~590 ASTM D-638 |

| Taber abrasion(mg) | 30~40 ASTM D-1044 |

| Tear strength(kg/cm2) | 155 ASTM D-732 |

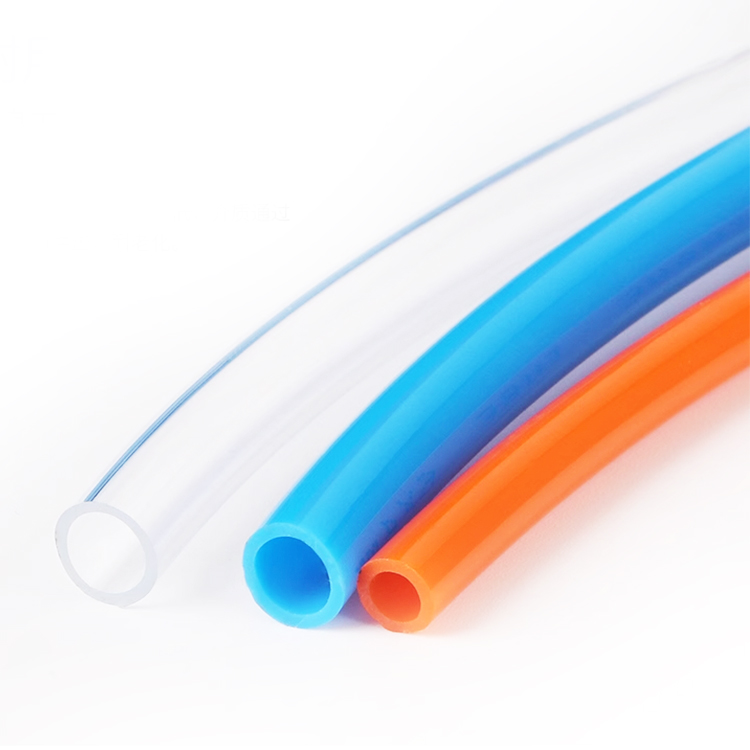

Product Performance:

◆ Excellent tensile strength, flexural performance, abrasion resistance, and solvent resistance.

◆ High tear strength, heat resistance, and transparency.

◆ Oil resistance, aging resistance, high hardness, and elasticity.

◆ Low susceptibility to oxidation, achieving a level 3 or higher resistance to yellowing.

Product Application:

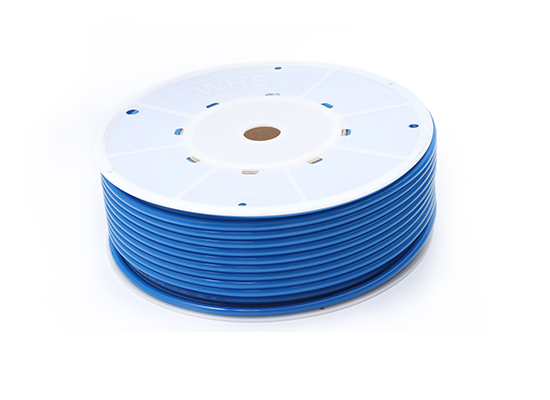

Our Ester-based Polyurethane tubings are widely used in various industrial fields, including hydraulic systems, pneumatic systems, chemical transportation, etc. Whether on construction sites, in machinery manufacturing plants, or automotive repair shops, Fokca products can provide you with reliable fluid transport solutions.

Difference Between Ester-based and Ether-based PU tubings:

Polyester-based polyurethane tubing exhibits better performance in some chemical media, relatively more cost-effective. Generally has good heat resistance, mechanical properties, and chemical stability, but may become brittle at low temperatures.

Polyether-based polyurethane tubing, typically has better elasticity and flexibility, better cold resistance, less prone to becoming brittle. However, its heat resistance and chemical stability may be slightly inferior to polyester-based polyurethane tubing.

Any questions or requirements regarding our polyester-based polyurethane hoses, please feel free to Contact us. We are dedicated to providing you with high-quality service and solutions.