A hydraulic valve is a control element used to regulate the flow, direction, and pressure of hydraulic oil, serving as the “control center” of a hydraulic system.

Hydraulic components are the individual parts that make up a hydraulic system, working together to generate, control, and transmit hydraulic power. For example the hydraulic pump is responsible for converting mechanical energy into hydraulic energy by pressurizing the fluid. Other Hydraulic components playing different roles.

Hydraulic systems have efficient, precise, and powerful power transmission capabilities in precision machining or intelligent manufacturing, etc. Hydraulic components are independent but interconnected parts that together form hydraulic systems and play a crucial role in modern industrial and mechanical equipment.

When selecting hydraulic components, in addition to considering parameters such as system pressure, flow rate, and temperature, it is also necessary to customize the configuration according to the specific application environment. For devices that require lightweight and fast response, pneumatic components can sometimes be used in combination to enhance the flexibility and efficiency of the overall system.

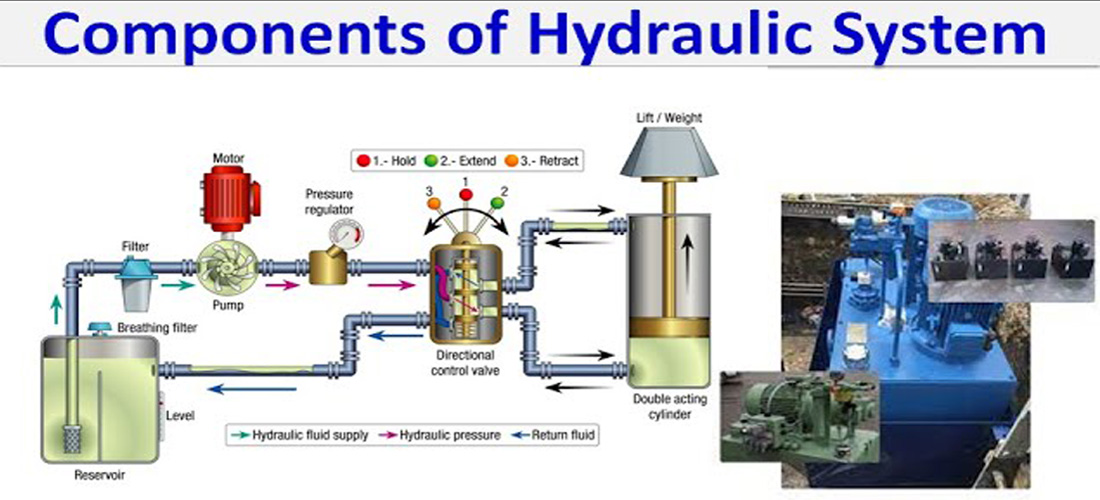

A typical hydraulic system is composed of five major categories of components. These parts work together as hydraulic fluid flows through them to generate, control, and transmit power.

Hydraulic pump: It is the power component of the hydraulic system, mainly responsible for converting mechanical energy into hydraulic energy by pressurizing the fluid.

Hydraulic valves: It is a regulating and controlling component used to control the direction, pressure, and flow of hydraulic oil within a system.Common types of valves include directional control valves, pressure relief valves, and flow control valves.

Hydraulic actuators: such as hydraulic cylinders and motors, convert hydraulic energy into mechanical motion to perform work,It is an execution component.

Hydraulic reservoir: Store hydraulic oil and also have a cooling function.

Hydraulic hoses and fittings:transport the hydraulic fluid between components while maintaining pressure, while hydraulic filters remove contaminants from the fluid to protect the system from damage. It is a transmission component of the hydraulic system.

Moreover,Hydraulic quick couplings allow for quick connection and disconnection of hydraulic lines without fluid loss or contamination, making maintenance and adjustments easier,such as the widely used ISO 7241 A Quick Coupling,is widely used in agricultural machinery, construction equipment, and industrial hydraulic systems due to their simple structure, strong interchangeability, and reliable sealing.

A hydraulic system operates based on Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. When the hydraulic pump is activated, it draws fluid from the reservoir and pressurizes it. The pressurized fluid flows through hoses or pipes to the control valves, which direct the fluid to the actuator based on the required motion. The actuator, such as a hydraulic cylinder or motor, converts the hydraulic pressure into mechanical motion, producing linear or rotational force.

After the work is completed, the fluid returns to the reservoir to be cooled and filtered before being recirculated in the system. This closed-loop design allows for continuous operation and precise control of movement and force.Browse this article for more detailed information on how hydraulic systems work.

Hydraulic systems are widely used because they can generate high force while maintaining precise control. They have a high power density, meaning they can transmit large amounts of power using relatively small components.

The ability to adjust the pressure and flow rate allows for smooth and accurate operation. Hydraulic systems are equipped with overload protection through pressure relief valves, which prevent damage by automatically releasing excess pressure.

Their durable design allows them to withstand harsh working conditions and heavy loads, making them highly reliable. The flexible nature of hydraulic systems also makes them adaptable to different applications by modifying the configuration and components used.

Choosing suitable hydraulic components is crucial for the optimal functioning of hydraulic systems, depending on the industry in which they are applied. A properly matched hydraulic component can not only improve the efficiency of the hydraulic system, but also significantly reduce equipment failure rates and maintenance costs. The following are the precautions to be taken when selecting hydraulic components.

Pressure rating is one of the most fundamental and critical technical indicators of hydraulic components. Each component has its rated pressure and maximum allowable pressure during design. When selecting, it is necessary to ensure that the pressure rating of the components meets or exceeds the maximum working pressure of the system, and to reserve sufficient safety margin for pressure fluctuations.

The materials used in hydraulic components directly affect their wear resistance, corrosion resistance, and overall lifespan. For example, in corrosive environments such as the ocean or chemical industry, stainless steel or special anti-corrosion coating materials should be selected; In high load or high temperature environments, alloy steel and high-performance seals will be more reliable. Other components such as sealing rings, hydraulic considerations for their sealing performance in different fields.

Hydraulic components need to be compatible with other components of the hydraulic system, including:

Interface specifications: Are the thread standards and connection forms consistent;

Working medium: whether the component is suitable for specific hydraulic oil or other liquids;

Size and installation method: Can it be seamlessly installed into the existing system;

Compatibility of electronic control systems, such as sensors, proportional valve controllers, etc.

Hydraulic Quick Couplings It is a transmission component of the hydraulic system.Fokca provides Quick Couplings Hydraulic designed for efficient and reliable connection and disconnection of hydraulic lines.

These couplings ensure minimal fluid loss and prevent contamination, making them ideal for high-pressure and heavy-duty applications.

◆ Hydraulic Cylinders

A hydraulic cylinder is an actuating component that uses the pressure generated by hydraulic oil in a sealed chamber to drive the piston for linear reciprocating motion or oscillating motion.

◆ Hydraulic Valves

The maintenance of hydraulic components is more frequent compared to pneumatic components due to the use of media and high-pressure application environments in hydraulic systems. The following are maintenance requirements for hydraulic components:

Although the hydraulic system itself relies on hydraulic oil to transmit energy and provide some lubrication, certain components wear severely in high-pressure environments and still require regular application of specialized lubricating grease. Reasonable lubrication can effectively reduce friction and wear, and improve operational stability.

Due to the use of hydraulic oil, impurities, particles, or moisture in the hydraulic system can accelerate component wear, block valve ports, and even damage seals. It is recommended to regularly replace hydraulic oil, keep the oil tank sealed, and install high-efficiency filter elements to control pollution.

Suggest developing a periodic inspection plan, with a focus on checking the following:

Are there any leaks in the joints and pipelines;

Whether the pressure gauge and sensor are working properly;

Are there any abnormal wear or jamming on the hydraulic cylinder and valve body;

Is the color and odor of the oil abnormal, and is the oil level sufficient.

We are a professional manufacturer of startup equipment based in Ningbo, specializing in pneumatic and hydraulic components. Our product range includes different kinds of Hydraulic Quick Couplings as well as Pneumatic Components、Hoses & Connectors、Valves and other types of products.

As an automation equipments manufacturer and pneumatic products corporation, we are dedicated to delivering the best in pneumatic products for various industries.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap