Globe valves are essential components in fluid control systems, designed to regulate, stop, and start the flow of liquids and gases. Their name derives from the spherical body shape, which typically contains a movable disk-type element and a stationary ring seat.

The traditional globe valve is a type of manually operated mechanical valve. It regulates flow by moving the valve stem up and down through mechanical means, such as turning a handwheel, to control the position of the valve disc. With the development and application of automation, globe valves now also have automated versions that can be combined with various actuators, saving labor.

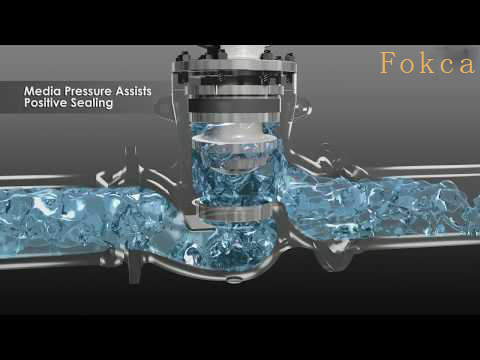

The working principle of a globe (mechanical) valve is to regulate or shut off fluid flow by the up-and-down movement of its internal closing component — typically a solid or hollow spherical disc. This very component is precisely why it is called a "globe" valve.Automative pneumatic globe valves are widely used in industries that require accurate throttling, stable flow rates, and reliable shut-off performance.

Precise Flow Regulation:One of the core advantages of a globe valve is that most pneumatic globe valve designs employ linear or conical valve disc and seat structures, enabling highly precise flow regulation even with minimal valve stem movement.

Excellent Shut-off Capability:Another advantage is that even under high-pressure conditions, a globe valve can achieve tight shut-off. The balanced sealing surface formed between the valve disc and the seat ensures good sealing performance and immediate closure.

Wide Material Selection:Globe valves are used across many industries because they are available in various materials, including carbon steel, stainless steel, alloys, etc., allowing them to handle different media and meet diverse industrial requirements.

Multiple Actuation Methods:A key feature of automated globe valves is that they eliminate manual operation. The valve disc can be driven by electric, pneumatic, or hydraulic actuators, making the valve compatible with various automation systems.

High Flow Resistance:Globe valves usually have an S-shaped or bent flow path, which aids precise flow regulation but also causes significant pressure loss when fluid passes through.

High Energy Consumption:Due to the pressure loss, the downstream system may not meet its requirements unless the upstream supply is designed with pressure margin. This means the medium must be delivered at higher-than-required pressure, which can increase energy consumption.

Size and Maintenance:The valve has a complex structure and thick body, and the sealing surfaces between the disc and seat require regular maintenance.

A globe valve consists of three kinds component combination include support, control, and execution.

Body and Bonnet:

The outer casing that houses the internal components.

Plug and Seat:

The disk moves perpendicular to the seat to control fluid flow.

Stem and Actuator:

The stem connects the disk to the actuator or handwheel, allowing manual or automated operation.

When the handwheel or actuator is turned, the stem moves the disk towards or away from the seat. This movement allows precise flow control, making globe valves ideal for throttling applications.

Globe valves come in various designs, each suited for different operational needs:

Pneumatic Globe Valve:

The pneumatic actuator drives the valve stem to move up and down, enabling fast opening and closing with precise flow control.

Manual Globe Valve:

The handwheel mechanically operates the valve stem to achieve slow opening and closing.

Angle Globe Valve:

Allows fluid to change direction by 90 degrees, reducing the need for additional pipe fittings.

Due to their design and functionality, globe valves are used in various industries:

Water Treatment Plants:

Used for regulating water flow and pressure.

Oil and Gas Industry:

Controls the flow of petroleum products and natural gases.

Power Plants:

Employed in steam systems where precise flow regulation is critical.

Chemical Processing:

Used to handle corrosive and hazardous fluids safely.

Globe valves play a crucial role in fluid regulation across multiple industries. Their ability to provide precise flow control, combined with excellent shut-off capabilities, makes them indispensable in various applications. By selecting the appropriate type and material, industries can optimize their processes, ensuring efficiency and reliability in fluid handling systems.

| Comparison Item | Globe Valve | Ball Valve |

|---|---|---|

| Flow Control Accuracy | High | Low |

| Stability at Low Flow Rates | Excellent | Poor |

| Repeatability | High | Low |

| Control Characteristic | Linear / Equal Percentage | Non-linear |

| Suitability for Flow Control | Highly suitable | Not recommended |

If your system requires precise compressed air flow control, choose a Globe Valve; if it only needs on/off operation, choose a Ball Valve.

Because the closing component (disc) inside the valve is usually a solid or hollow sphere or a similar spherical plug.

A gate valve is used for full on/off flow with a straight-through path, while a globe valve is designed for precise throttling and flow regulation.

Yes, globe valves are typically unidirectional, with fluid entering from below the seat and exiting from above it.

A pneumatic globe valve is an automated flow-control valve driven by a pneumatic actuator to achieve fast and precise throttling or on-off operation.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap