Shock absorption: When the piston reaches the end of its stroke, the cushion dissipates kinetic energy to prevent direct metal-to-metal impact.

Noise reduction: Lowers the impact noise generated during high-speed cylinder operation.

Extended service life: Reduces mechanical wear on the cylinder barrel, piston rod, and end covers.

Improved stability: Ensures smoother motion and enhances positioning accuracy.

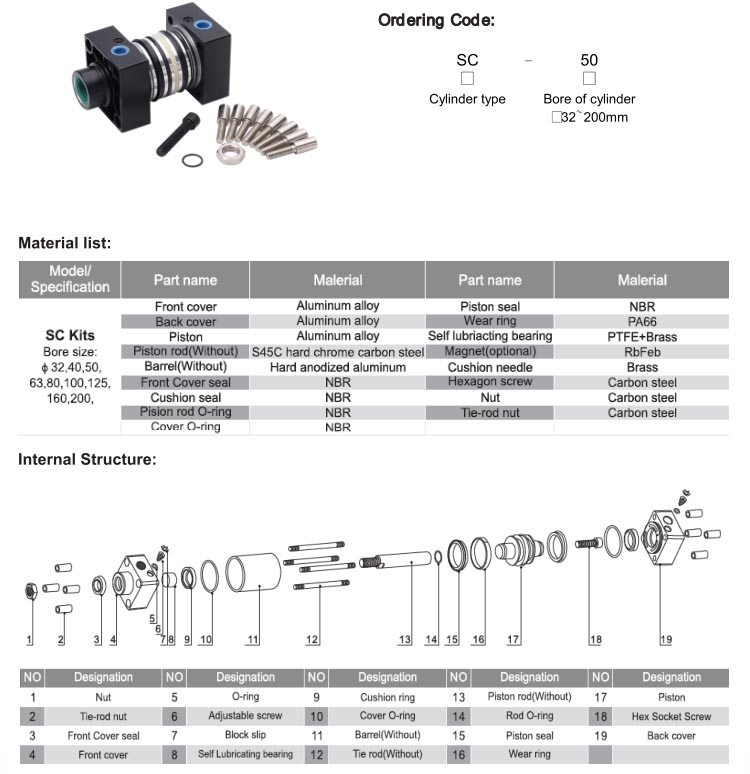

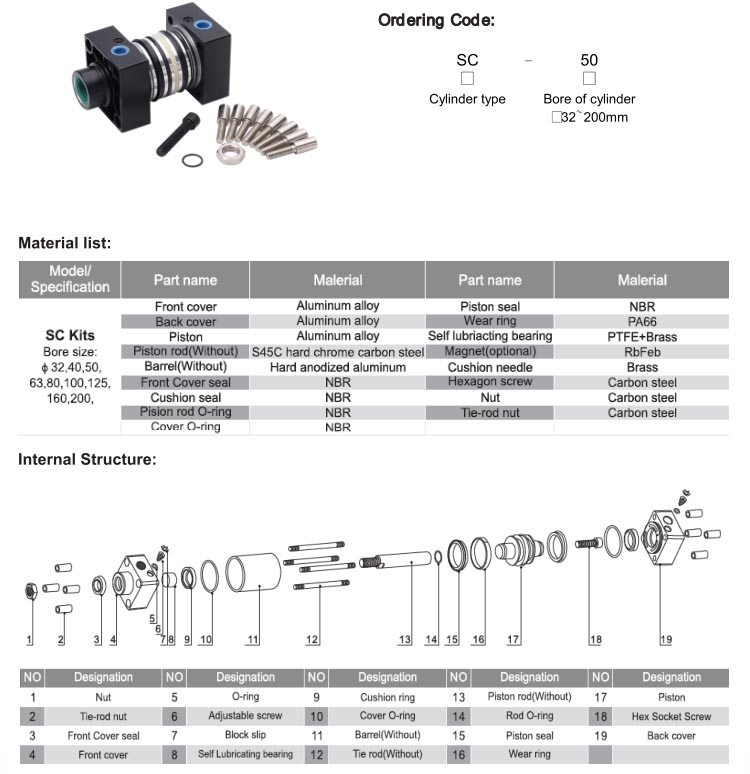

The cylinder shock absorber functions when the piston reaches the end of its stroke. It dissipates kinetic energy through elasticity and damping, preventing direct metal-to-metal impact, reducing wear, extending the service life of the cylinder, improving operational stability, and lowering noise. Different types of cylinder cushioning kits must match the cylinder’s dimensions and specifications; otherwise, instead of providing protection, they may have the opposite effect. For example, an SC double-acting cylinder requires an SC-type cylinder cushioning device for proper adaptation. With a wide adjustable cushioning range, this device offers not only cushioning compatibility but also interchangeability of related parts such as cushioning elements, sealing rings, and accessories.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap