Equipment that utilizes pneumatic principles to achieve mechanical motion includes automated control systems and mechanical devices, used in industrial processes such as production, processing, packaging, and material handling.

Pneumatic devices are not only used in industrial applications; they are actually much closer to our daily lives than we might think. If you observe carefully, you will find many examples of pneumatic components in action. For instance, the "hiss" sound when a bus door opens or closes is the sound of a pneumatic cylinder at work. Similarly, the automatic motion-sensing soap dispensers often rely on a small cylinder inside to operate, though they typically function as a complete system.

These actions are made possible by the use of air tubes to transport "energy" and connectors to securely and tightly link everything together. Pneumatic components are particularly well-suited for hobbyists and DIY creators! They are easy to control, modular, and relatively low-cost, allowing makers to give their creative projects "steel-like" muscles. With these components, one can easily build fun projects like automatically opening treasure chests, remote-controlled model robots, or automated plant watering systems.

Equipment that utilizes pneumatic principles to achieve mechanical motion includes automated control systems and mechanical devices, used in industrial processes such as production, processing, packaging, and material handling.

For modern enterprises that require automated production, smart manufacturing, and industrial modernization, such equipment is crucial for improving production efficiency and reducing manufacturing costs.

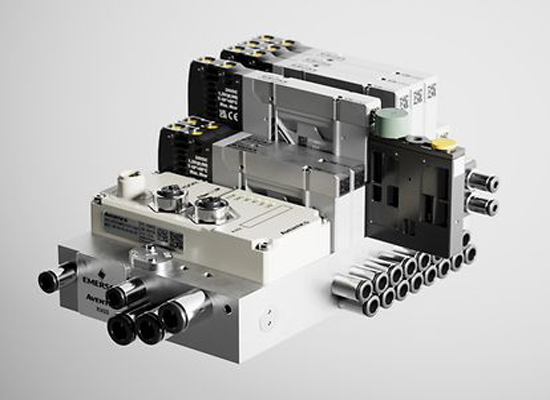

Since the direction, pressure, and flow rate of compressed air can be adjusted, switched, and logically controlled through various control components (such as valves, sensors, and PLCs), automatic control of actuators can be achieved when control signals are transmitted to these components.

The Can Crusher Machine is a device that uses compressed air as its power source and operates through pneumatic components to automatically crush aluminum or steel cans.

The Can Crusher Machine consists of several pneumatic and control elements, including:

Pneumatic cylinder

Solenoid valve

Air preparation unit (FRL – Filter, Regulator, Lubricator)

Fittings and air tubing

Sensors

The machine features a simple structure, low cost, easy maintenance, fast response, and reliable operation.It can achieve pneumatic automation through either manual control or intelligent control systems.

Recycling and Environmental Protection Industry:Used to compress aluminum cans to reduce their volume, making them easier to transport and recycle.

Industrial Production Lines:Serves as an auxiliary device for waste material handling or packaging systems.

Vocational Education and Engineering Training:Functions as a pneumatic teaching apparatus for demonstrating pneumatic and automation control principles.

Beverage Manufacturing Industry:Used in canning production lines for waste material handling or packaging optimization.

Solenoid valves are all automated control components. Under the guidance of an electrical signal, the solenoid coil generates electromagnetic force to directly control the movement of the valve core, requiring no actuator and no manual operation to control the fluid or airflow.

Other pneumatic control valves can also achieve automated operation, usually requiring a pneumatic actuator, typically a combination of a cylinder and a solenoid valve. The solenoid valve acts as a bridge between the actuator and the control system, transmitting signals back and forth. With valve sensors providing action feedback, this series of pneumatic components forms a complete automated pneumatic loop system.

The main advantage of using pneumatics in automation systems is their simplicity, reliability, and cost-effectiveness in providing linear and rotary motion.Pneumatic systems use compressed air as the power source, which makes them:

Safe and clean – Air is non-flammable and leaves no residue, making it ideal for food, medical, and packaging industries.

Simple and reliable – Fewer moving parts result in easy maintenance and long service life.

Fast and responsive – Pneumatic actuators can achieve quick motion cycles with precise control.

Cost-efficient – The components (cylinders, valves, fittings) are relatively inexpensive and easy to install.

Energy-flexible – Air can be stored, distributed, and used in multiple devices simultaneously.

A pneumatic system is an automated actuation system that uses compressed air as its power source, primarily designed to perform mechanical actions such as pushing, clamping, pressing, and moving.Its core advantages lie in its fast response, simple structure, and easy maintenance, enabling highly efficient and stable motion control in industrial production.

In an automated pneumatic system, the pneumatic cylinder serves as the actuator that generates linear or rotary motion, while the solenoid valve acts as the control center that regulates airflow direction and pressure to control the cylinder’s movement.When the system receives an electrical signal from an upper controller or PLC, the solenoid valve switches the air circuit, causing the cylinder to extend, retract, or perform other programmed actions—thus realizing automated mechanical motion.

By combining solenoid valves with control signals, pneumatic systems can not only achieve single-action control but also perform sequential control, interlocking operations, and remote control through programmed logic.

Within the control system of an automated device, sensors are responsible for collecting various signals—such as cylinder position, pressure status, and workpiece presence.These signals are transmitted in real time to the PLC controller, which processes them according to pre-set logic programs to determine whether the system conditions meet the criteria for the next action.

When the logical judgment results in an “execute” command, the control system outputs an actuation signal that drives the solenoid valve to switch the air circuit, thereby controlling the pneumatic cylinder to perform the corresponding movement (e.g., pushing, clamping, or pressing).

Once the action is completed, the sensors again collect new state signals and send them back to the PLC, forming a complete control–actuation–feedback–closed-loop process.Through this closed-loop control, pneumatic systems can achieve fully automated operation—from simple single actions to complex sequential controls.This not only greatly improves production efficiency and precision, but also enhances the system’s safety, reliability, and level of intelligence.

As pneumatic components become increasingly intelligent through the integration of smart accessories, they are able to generate more data points to feed back into the control system. These data include usage statistics, diagnostic information, and service life data, which can be used to maximize system uptime, control energy consumption, and improve operational efficiency.

By combining pressure control with directional control, the control system enables visualized and logical control, significantly enhancing the controllability and standardization of pneumatic technology. This advancement increases its value and applicability across a wider range of automation scenarios.

Smart pneumatics provide more precise, efficient, and optimized control for automation applications within manufacturing processes.When pneumatic technology and automation technology work together, factories become more efficient, cleaner, and more energy-saving.

Links: www.fescolo.com(Pneumatic)

FOKCA ©1998-2025 All Rights Reserved Sitemap